A Tunnel & Set Pasteurizer Will Assist You Accomplish A Fresh, Tasty, As Well As Quality-Aerated Drink In A Portion Of The Time

A Tunnel & Set Pasteurizer is a food pasteurizer that includes a glass pitcher, condenser, stainless steel drum, and also a hose. A customer guidebook is also included in the package. The device links into a typical wall surface outlet. After connecting to the system, the item is travelled through a pre-heated paddle top right into the shut drum cover.

The passage and also batch pasteurizers are included a heated glass bottle, a condenser, as well as a stainless steel drum. The unit is very easy to set up and also preserve. They are economical as well as are safe for use. A Passage & Batch Pasteurizer works with both framed as well as open central heating boilers. just click the next article is shut throughout the procedure. As soon as the process is total, the glass bottle is removed. https://skillet.lifehacker.com/how-and-why-to-pasteurize-eggs-with-your-sous-vide-co-1795471604 will heat up and afterwards turn off.

“A BASIC GUIDE TO THC-INFUSED BEVERAGE PASTEURIZATION”

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) June 14, 2022

Article Release for Brewmasters & Beverage Makers, sponsored by PRO Engineering / Manufacturing Inc.

Click for full article: https://t.co/ysBKHhEA2t

PRO Engineering / Manufacturing Inc.

414-362-1500 pic.twitter.com/8f0pd7WCYH

Each Passage & Set Pasteurizer has its very own benefits. The device is mobile, easy to use, and comes with an insulated glass pitcher, pre-heated paddle top, as well as stainless-steel drum and also tube. The device also includes a customer's handbook as well as calls for a standard wall surface outlet. It has a temperature-regulated heavy steam generator and also can warm up to 1,000 ° F. The system will certainly additionally disinfect a selection of foods as well as beverages.

Many Passage & Set Pasteurizer systems include a pre-heated glass pitcher, condenser, and also a stainless-steel drum. A customer's guidebook is also included. Utilizing the equipment is simple, as well as it needs just a conventional wall surface electrical outlet. The system will call for a source of power, which is consisted of in the bundle. The tools has a stainless-steel tube, glass carafe, and also heavy steam stick.

A Tunnel & Batch Pasteurizer system contains a glass pitcher, a stainless-steel drum, as well as a pre-heated paddle top. The whole system consists of a condenser, a stainless-steel drum and an individual's guidebook. A common installation needs a basic wall outlet. A pre-heated paddle top is positioned inside the drum as well as rotated.

A Passage & Set Pasteurizer is made with advanced development and is cost-effective as well as easy to use. A Passage 'Set Pasteurizer' is an efficient as well as effective method to sterilize liquid items. It can be used for any type of type of item, and it has a range of features to match every application. Whether you're looking to deal with warm water for residential or industrial purposes, this unit is the perfect solution.

A Tunnel & Set Pasteurizer comes with a stainless-steel drum as well as a glass pitcher. It's developed to heat up a variety of items. A solitary tunnel can heat a gallon of milk in regarding 2 mins, and also each area is heated to a specific temperature level. When the procedure is complete, the glass bottles are stored in the secured drum until the time for the following set prepares.

A Passage & Set Pasteurizer is a rapid as well as effective beer pasteurizer that permits you to make fresh beer in your home. This device transfers warmth from the developing process to the beer rapidly and also easily. The outcome is a fresh as well as scrumptious drink, and also it's far better than any kind of commercially-produced drink. These units likewise make sure far better safety and even more tasty homemade beverages. So, why wait for a business system when you can have a fantastic item in mins?

A Passage & Set Pasteurizer has multiple components and also attributes. It consists of a glass carafe, condenser, a stainless steel drum, and a tube pipeline. A typical model has 4 separate parts, consisting of a condenser, glass carafe, and a stainless-steel tube. All of these components are compatible with a selection of bottled liquids and are easy to use.

A Passage & Batch Pasteurizer is a fantastic option for a house brewery. These machines supply quick warm transfer from the developing process to the beer, making it the ideal choice for the best beer. A lot of commercially-available beer-making bundles don't have the essential ingredients needed for a quick brew.

Keep Reading To Learn More Regarding The Tunnel Pasteurizers For Beer & Drink Makers

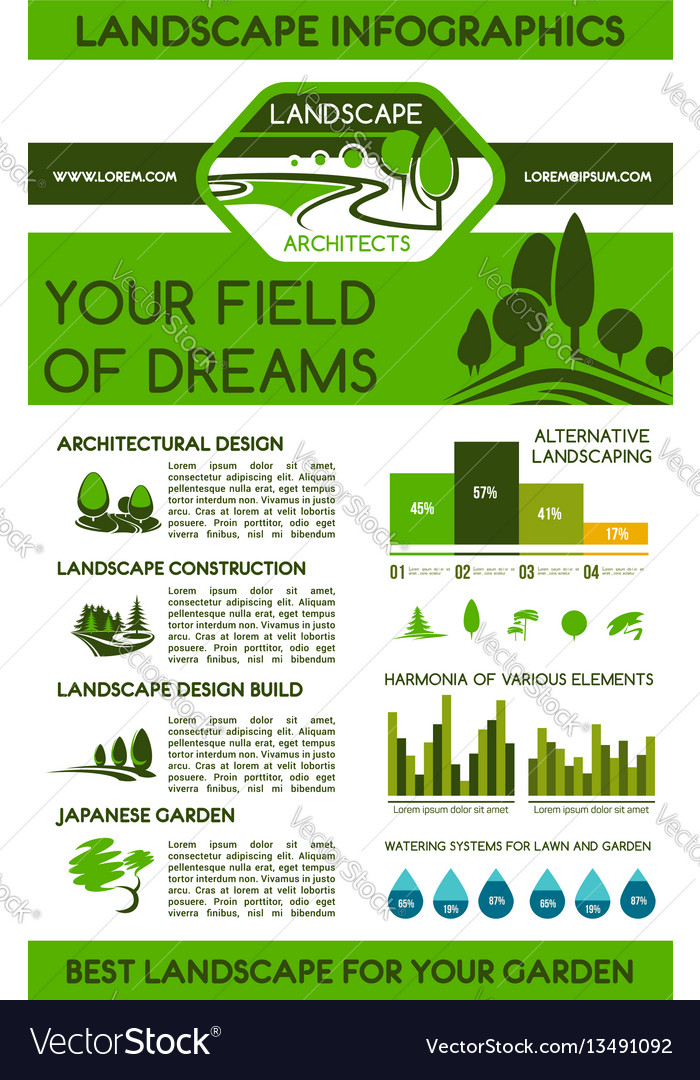

The tunnel pasteurizer is a mechanical device that warms the food or beverages as they are conveyed with it. The tool has numerous components that each have their very own water spray system, collection sump, circulation pump, as well as screen/filter box. If one of these elements stops working, it can influence the total safety and security, procedure integrity, bundle high quality, as well as complete price of possession of the center. To stay clear of such problems, it is important to maintain an effectively working tunnel pasteurizer.

The procedure of pasteurization involves the product passing through a stainless-steel passage that is filled with steam. The procedure basins lie within the tunnel as well as are made up of tubes. The water that runs off the packages is collected as well as reused. Passage pasteurizers are offered in single and also double deck variations. Solitary deck versions are a lot more typical in the U.S. developing market. Double-deck styles are extra vulnerable to clog.

A Tunnel pasteurizer is a beneficial tool for big quantities of pasteurised products, especially carbonated items. A sluggish conveyor passes the loaded as well as topped containers through the tunnel while they go through a water spray. The procedure is quick as well as reliable as well as can be easily incorporated right into bottling and identifying lines. Passage pasteurizers are available with a variety of functions and also features. These devices are offered in a range of measurements and styles, which can be custom-made to meet the demands of the consumer.

In addition to making certain the safety and security of items, A Tunnel pasteurizer offers several other advantages. Depending upon the water chemistry of the passage pasteurizer system, the bottles can encounter top quality problems that can lead to unsightly iron rust spots on the crowns of the bottles. Unlacquered cans might also experience the fading of decoration and also not natural salt precipitation on the plan. Tunnel pasteurizers supply a more efficient method of pasteurizing beverages, as well as can assist in saving a lot of money while doing so.

In addition to set pasteurizers, there are batch pasteurizers that provide heavy steam injection to the water. These systems are readily available in a selection of styles as well as are suitable for residential and commercial installments. They run within the flow line of a central home heating central heating boiler. They protect against the warm exchangers from obtaining blocked. browse around this web-site can be set up several times, making it a functional alternative for residence and industrial setups.

While numerous consumers may think of the process of flash pasteurization as simpler and quicker, it is very important to keep in mind that passage pasteurization is usually the very best choice for some foods. Tunnel pasteurizers are an effective and also quick means to make a variety of foods risk-free for usage. Tunnel pasteurizers are an essential part of a brewery's manufacturing process. They make it faster, extra efficient, and also extra efficient.

When compared to various other sanitation processes, batch pasteurizers are a lot more efficient and flexible. The latter are utilized to sterilize a variety of food. They are a functional means to quicken home developing. They utilize controlled temperatures, while the other techniques require experimentation. The temperature must be properly set before the creating process starts. By following the temperature standards, you will certainly help ensure the flavor stability of the items. You can likewise maintain your brewery secure from contamination by complying with excellent hygiene methods.

Passage Pasteurizers are an excellent selection when the shelf-life of your beverages is very important to you. The procedure works for food and beverages and likewise assists protect the contents of bottles. The tunnel pasteurizer lowers the existence of microorganisms and suspends enzymes in beverages. As soon as the called for temperature level is attained, the procedure can be finished in less than a minute. These makers are exceptionally energy-efficient, making them an excellent selection.

Just like any kind of equipment, installations are critical for precise results. Guarantee that measuring points lie in the correct locations to get an accurate representation of the tunnel's temperature. In addition, a great calibration system has sufficient networks to check the procedure distribution system. It must also include information loggers such as TrackSense Pro cordless data loggers that tape information at regular periods. They should be precise, have enough networks, as well as record pressure at intervals not going beyond one min.

Exactly How To Choose The Passage Pasteurizers As Well As Set Pasteurizers For Beer & Beverage Makers?

Passage Pasteurizers are devices that warmth items such as sodas, beer, and also acid protects to a temperature below the point at which they are secure for consumption. The containers are filled onto one end of the pasteurizer conveyor belt and then passed beneath sprays of warm water. The water is heated up at temperatures from 60 to 100degC. The size of the pasteurization procedure depends on the sort of container. To make the procedure reliable, Passage Pasteurizers are made to disinfect items as rapidly as possible.

Big Passage Pasteurizers are made use of in business developing procedures. These pasteurizers heat beer to 140F and hold it there for a predetermined time period. After the time is up, the beer is cooled off by being immersed in hot vapor or splashed with cold water. A tunnel pasteurizer is a typical part of several large-scale brewing centers. Tunnel pasteurizers are the most common selection of pasteurizers.

Set pasteurizer systems typically consist of a stainless-steel drum with a pre-heated glass carafe. The system has a condenser, funnel, as well as complementary devices. A lot of these systems are designed for home usage as well as feature client overviews as well as insulated covers. Numerous additionally have the option of an integrated cooling system. Along with set pasteurizers, there are additionally tunnel pasteurizers that are furnished with heavy steam shot.

The various parts of a tunnel pasteurizer can affect the high quality of the finished beer. For instance, if the beer has been pasteurized expensive, it can lead to unpleasant "pasteurization tastes" as well as turbidity. A sterilized beer can also contain yeast as well as various other impurities that can bring about bottle bursting and unwanted development. Eventually, this can influence the high quality of the packaged item, the safety and security of the customer, as well as your profits.

Because tunnel pasteurizers are such efficient equipments, they are made use of in a wide variety of industries. The goal of the tunnel pasteurizer is to eliminate microbes, stop fermentation, and also maintain shelf stability. These makers go through considerable heat modifications and also caustic cleansing chemicals. Furthermore, busted bottles can damage the pasteurizer. Tunnel pasteurizers from PRO Engineering have years of experience in designing and building them.

To check the temperature and also time taken for the bundles to go through the pasteurizer, a pasteurization device display is made use of. It is made up of software and hardware that travels with the item throughout pasteurization. It downloads dimensions to a notebook computer and also determines PUs. It likewise controls the water sprays inside the passage as well as can be controlled. There are different temperature levels and times for different products, so it is essential to carefully consider the temperature level and also time required for the item to be sterilized.

When selecting a passage pasteurizer, consider its dimension and type. These machines can be found in a variety of dimensions and measurements, and are based on the kind of product being sterilized. Depending on the type of foodstuff, tunnel pasteurizers might be a vital part of a manufacturing procedure. go now get rid of germs, enzymes, and other microbes that can make products risky to consume. So, pick the best one for your requirements.

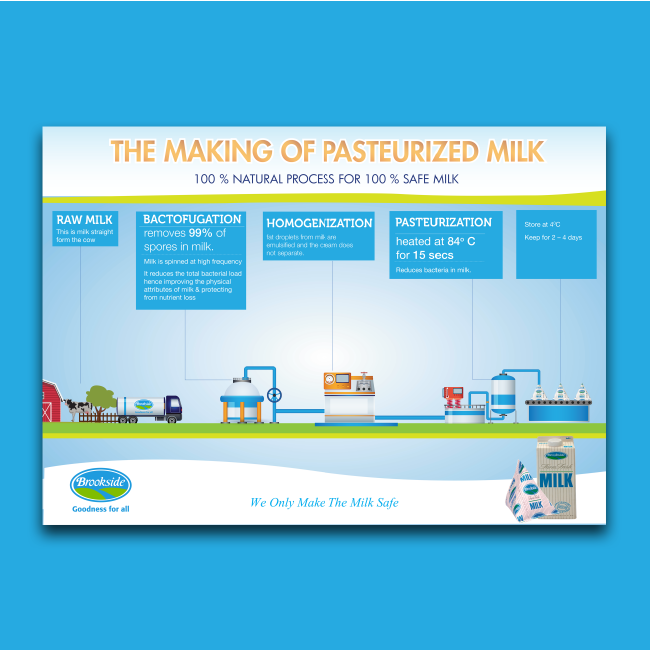

Millisecond Technologies' procedure entails splashing milk right into a warmed chamber. The milk is then heated at a price of 72.7 degC for 20 milliseconds. Combined with fast depressurization, the milk is damaged of all traces of microorganisms. Commercial MST plants can refine up to 240,000 litres per hr. At 4 degC, sterilized milk has a service life of 60 days.

Historically, pasteurization was thought about an outcast technique among tiny and also independent breweries. Independent makers thought that pasteurization was an unnecessary concession in between flavor and shelf-stability. The technique seemed antithetical to the craft values when initially introduced. Craft beer continued to expand as well as nationwide brand names went along. National distribution suggested even more containers traveling longer ranges, as well as enthusiasts became more adventurous with the dishes they were consuming. In spite of this, the microbial load in craft beer boosted. This lowered shelf-stability and also reduced consumer confidence.

What Are The Distinctions In Between Tunnelpasteurizers Vs Set Pasteurizers

TunnelPasteurizers are utilized to sanitize the materials of little bottles, such as a glass of wine, spirits, and beer. These pasteurizers warm the elements in a container loaded with hot water and allow them to relax for a while prior to relocating to a conveyor belt. During the pasteurization procedure, the water is pumped from the discharge end to the infeed end. This process guarantees that all of the components are thoroughly pasteurized. A vacuum cleaner system is likewise set up on many conveyor belts to capture broken bottles.

When sterilizing fluid in containers or canisters, Tunnelpasteurizers provide both re-cooling and also heat exchange. This warm exchange system incorporates pasteurization and also re-cooling, and its optimized nozzle system is designed to supply a high degree of warm exchange with the item. Water financial savings systems are also included, which collect water and also other waste and recycle the water in the Tunnelpasteurizer. As long as the process is done according to the standards and also security standards, a passage pasteurizer is an affordable alternative.

Modern Tunnelpasteurizers have a water saving system that optimizes water consumption. Tunnelpasteurizers are offered in a variety of sizes and capabilities, so you can choose one that finest fulfills your needs. Furthermore, a portable Tunnelpasteurizer is smaller sized in size, making it perfect for small processes. Regardless of its small size, the compact model permits you to conserve room in your manufacturing location, which is necessary in the manufacturing procedure.

A passage pasteurizer is a reliable equipment that removes all recurring microorganisms in food and also beverage products. They are readily available in a range of dimensions and also are used in the food and also drink sectors to eliminate microbes, stop fermentation, as well as give shelf stability. Because Tunnelpasteurizers experience big temperature level variants, caustic cleaning chemicals, as well as enormous mechanical stress and anxiety, they are very sturdy as well as reliable. A damaged container can seriously damage a passage pasteurizer. PRO Design designs and also develops Tunnelpasteurizers and has more than 4 decades of experience.

On the other hand, set pasteurizer systems have been made for household installations. They consist of a stainless-steel drum, a pre-heated glass pitcher, a condenser, and complementary tools. Many set pasteurizers are made to be attached to a wall surface electrical outlet and come with consumer manuals. Throughout the pasteurization process, the product travels through stainless steel tunnels filled with injected vapor. The temperature level increase is slow-moving as well as non-uniform.

Unlike standard sterilization methods, batch pasteurizers have a managed temperature level. Unlike https://www.opindia.com/2020/12/first-human-milk-bank-in-northeast-opened-in-guwahati-hospital/ , which include trial-and-error, the temperatures of Tunnelpasteurizers are thoroughly calibrated before the procedure starts. This guarantees that the final product maintains its taste as well as top quality while securing versus contamination. If you're planning on developing your very own beer, it's a good idea to start with a batch pasteurizer.

To gauge the temperature level in a passage pasteuriser, search for a tool that can record measurements. Normally, the gadget will have audible or visual alarm systems to signal the operator of a modification in temperature level. A static tracking gadget is likewise helpful for measuring temperature level. Tunnelpasteurizers can be easily monitored as well as made use of to check temperatures. So, pick the very best choice for your demands. And also, do not neglect to examine your product for any leakages!

Relying on the chemistry of the water in the Tunnelpasteuriser system, containers may experience high quality troubles. Some containers may experience rust areas on the crown of the bottle. Aluminium cans may likewise deal with staining. Additionally, unlacquered cans might experience fading in decoration. These issues may also affect the overall price of ownership of the product. As well as, the water chemistry in the pasteuriser can likewise negatively influence the packaging quality.

Tunnelpasteurizers are ending up being a lot more popular, as well as professional makers are finding them to be an efficient method to pasteurize beer for mass usage. In addition to business developing facilities, even more mid-tier craft breweries are going with Tunnelpasteurizers to guarantee the safety and quality of their product. Tunnelpasteurizers heat the beer to a temperature of 140 degrees Fahrenheit, then cool it down.

The control system of a Passage Pasteurizer includes software and hardware. The hardware travels with the item throughout pasteurization. It downloads the measurements to a notebook computer and computes the PU. Generally, the control systems are PLC-based. The programs made use of in these devices regulate the temperature level and time within the tunnel. If the temperature is more than the needed degree, the vapor valve opens and also closes according to the error.

Keep Reading To Read More Regarding The Passage Pasteurizers For Beer & Drink Makers

The tunnel pasteurizer is a mechanical device that heats the food or drinks as they are communicated via it. The gadget has various parts that each have their very own water spray system, collection sump, blood circulation pump, and screen/filter box. If among these parts falls short, it can influence the general safety, procedure dependability, plan top quality, as well as complete expense of ownership of the center. To stay clear of such issues, it is important to preserve an appropriately functioning tunnel pasteurizer.

The procedure of pasteurization includes the item travelling through a stainless steel passage that is saturated with steam. The process containers are located within the tunnel and also are made up of tubes. The water that escapes the bundles is collected and reused. Passage pasteurizers are offered in solitary and dual deck versions. Single deck designs are more typical in the U.S. brewing market. Double-deck layouts are more prone to blockage.

A Tunnel pasteurizer is a helpful piece of equipment for huge quantities of pasteurised products, specifically carbonated products. A slow-moving conveyor passes the loaded and covered bottles through the tunnel while they are subjected to a water spray. The process fasts and effective and can be quickly integrated into bottling and identifying lines. Passage pasteurizers are readily available with a wide range of features as well as functions. These equipments are readily available in a selection of dimensions as well as styles, which can be customized to meet the needs of the client.

In addition to making sure the safety and security of products, A Tunnel pasteurizer supplies many other advantages. Depending upon the water chemistry of the tunnel pasteurizer system, the bottles can encounter high quality problems that can lead to unattractive iron rust spots on the crowns of the bottles. Unlacquered containers might additionally struggle with the fading of decoration and also inorganic salt rainfall on the plan. Tunnel pasteurizers use an extra reliable means of pasteurizing drinks, as well as can assist in saving a lot of cash in the process.

Along with set pasteurizers, there are set pasteurizers that provide steam shot to the water. These systems are readily available in a range of styles as well as appropriate for domestic and also industrial setups. They operate within the flow line of a main heating boiler. They protect against the cozy exchangers from obtaining obstructed. A batch pasteurizer can be mounted multiple times, making it a sensible alternative for home and also commercial setups.

While many consumers may think of the procedure of flash pasteurization as simpler and also faster, it is essential to keep in mind that tunnel pasteurization is usually the most effective option for some foods. Tunnel pasteurizers are an effective and quick way to make a range of foods safe for consumption. Tunnel pasteurizers are an important part of a brewery's manufacturing procedure. They make it much faster, a lot more effective, and more effective.

When contrasted to other sanitation procedures, batch pasteurizers are extra reliable and versatile. The latter are utilized to decontaminate a selection of food. They are a sensible means to quicken residence developing. They use regulated temperature levels, while the various other methods need experimentation. The temperature needs to be effectively set before the establishing procedure begins. By complying with the temperature guidelines, you will certainly aid make sure the taste stability of the products. You can also maintain your brewery secure from contamination by adhering to excellent hygiene practices.

Tunnel Pasteurizers are a superb choice when the shelf-life of your beverages is necessary to you. The procedure works for food and also beverages as well as additionally helps maintain the materials of bottles. The tunnel pasteurizer decreases the existence of microbes and also inactivates enzymes in drinks. Once https://foodpoisoningbulletin.com/2017/raw-milk-products-cause-840-times-more-illness-than-pasteurized-milk/ called for temperature level is accomplished, the process can be finished in less than a min. These devices are extremely energy-efficient, making them an outstanding option.

Similar to any kind of devices, fittings are critical for exact results. Make sure that determining factors lie in the proper places to obtain an accurate representation of the tunnel's temperature level. Furthermore, a good calibration system has enough channels to check the procedure shipment system. It needs to likewise consist of data loggers such as TrackSense Pro cordless information loggers that tape-record information at routine intervals. They need to be precise, have enough networks, and also record stress at intervals not exceeding one minute.

You Must Take Into Consideration How Many Jobs You Require To Carry Out With A Skid Steer Prior To Buying One

A skid Steer is a functional item of construction devices. It can do a range of tasks from excavating to landscaping a park. Skid guides can be rented out or purchased for hire, and are usually utilized interchangeably. This blog will certainly explain the distinctions in between skid steers and also Bobcats, as well as assist you choose which one is ideal for your needs. Whether you're a beginner or an experienced professional, this versatile equipment will conserve you money and time.

The name Bobcat was first connected with the M444 Melroe Bobcat. This maker was tough and also fast, showing the bobcat qualities that had actually made it prominent. Today, the name "bobcat" is synonymous with the skid Steer. The firm started in 1947, when E.G. Melroe started the Melroe Production Business. In 1954, he partnered with bros from Western Minnesota that invented the very first skid Steer, called the Keller Loader, for turkey farmers. In 1958, Melroe Manufacturing purchased the legal rights to the Keller Loader and also started mass production.

When getting a skid Steer, it is essential to consider the variety of applications it will be utilized for. The skid Steer is utilized for various tasks, including snow elimination. The equipment is maneuverable, and also has double hydraulic arms that use high lifting capability. The ability varies from 1,250 to 2,700 pounds. With the capacity to adjust the speed separately of each side, a skid Steer can quickly steer in tight spots. There are many benefits to skid guides.

While many skid guides come equipped with augers, the backhoe is one of one of the most popular. It streamlines trench excavation as well as enables you to operate in mud and ice. These machines are sturdy as well as huge ability, as well as work for several building tasks. In addition, you can discover backhoe attachments for your skid steers. It is likewise feasible to purchase a design that has actually cast teeth, which aids you dig trenches with ease.

When you need to move or lift hefty materials, skid steers are your best option. You can buy attachments for various functions as well as branch out the capabilities of your devices. This can help you boost efficiency no matter what season you're in. Skid guides are likewise excellent for getting rid of areas. A smooth container will certainly make the task a lot easier, much faster, as well as extra efficient than a male can relocate by hand. The adaptability of skid guides is limitless and also you can locate something to fit your needs.

The first skid Steer was created in 1957, yet it was originally referred to as a three-wheeled loader. This machine was created by two brothers from Rothsay, Minnesota. They were hired by a local turkey farmer to create a maker that would allow him to move his flock from barn to delay with ease. They eventually marketed their invention to a Tools Dealership in Rothsay, Minnesota, and also continued to fine-tune it. The skid Steer has actually since ended up being a popular piece of heavy equipment for agricultural work.

As a versatile item of building equipment, the skid Steer loader is a great option. Its convenience allows it to do a range of tasks, from digging to lifting. It can additionally jackhammer concrete, load trucks, and also spread product. In addition to building as well as landscaping, the skid Steer is likewise utilized in numerous other locations. A skid Steer loader is flexible, efficient, and also light. If you need to move a big quantity of product in a short amount of time, a skid Steer loader is an outstanding choice.

With the proper accessories, a skid Steer works outstandingly for construction work. A skid Steer can also be furnished with a cement mixer, so you can finish a lot more tasks with the same maker. Another benefit of a skid Steer is its convenience of procedure. Building tasks can be extra reliable and also convenient when using a skid Steer, as well as it's simpler to make use of than a conventional forklift. You can use it for anything from landscaping to leveling a grass.

The skid Steer is versatile, with a number of different attachments to complete various jobs. https://www.equipmentjournal.com/construction-equipment/asv-launches-new-line-of-compact-track-loader-and-skid-steer-attachments/ can be changed with an auger, backhoe, and also trencher. These add-ons can dig a structure for a structure or dig a narrow porthole.Once you have actually decided which skid Steer will certainly function best for your demands, you can head out and also purchase the equipment.

Keep Reading To Read More Concerning The Differences In Between Skid Steer Tree Puller Vs Heavy-Duty Tree Puller

Investing in a skid Steer tree puller is an easy and reliable way to eliminate big trees from a landscape. The Stinger STP-34 has a twenty-inch high, twenty-four-inch vast guard as well as is fully bonded to the skid Steer's major frame. Developed to endure simply click the up coming article , this skid Steer add-on is developed for efficiency in one of the most hard settings.

A skid Steer tree puller is one of one of the most popular attachments readily available for skid steers. These accessories are furnished with steel plates that imitate jaws to get onto trees, posts, and various other greenery. They are utilized for landscape design, construction, and also farming jobs. Before purchasing a skid Steer tree puller, be sure to read through the item's instructions and also terms and conditions to make sure correct usage. You can additionally select one that comes with security functions, such as an automated shutoff and a low-speed setting.

The skid Steer tree puller can additionally be utilized to hair transplant trees. Unlike a standard tree-puller, a skid Steer tree puller enables you to remove the tree's root system without damaging close-by plants. Nonetheless, it is very important to note that tree survival is not guaranteed when it is hair transplanted. You should always dig a hole around the origins, as they can become broken otherwise. However if you are trying to find a rapid as well as efficient means to eliminate trees, a skid Steer tree puller is the very best option.

The Heavy-Duty Tree Puller is a functional landscape design add-on. It has jaws outfitted with serrated teeth that successfully pull up origins. Besides, this device is also valuable for eliminating huge messages, fence blog posts, as well as rocks. In addition to trees, it also makes it easy to establish blog posts and also fences. If you intend to do this job with less effort, you can get the MTL Attachments Tree Puller.

Prior to using a skid Steer tree puller, see to it to know all the safety treatments. Prior to starting your project, remove any kind of barriers that may remain in your method. Likewise, remember to disengage the clutch and safety decals before using the skid Steer. During procedure, you ought to stay in the driver seat as well as use your safety belts. The skid Steer tree puller can be unsafe, so see to it that you use safety and security gear in any way times.

The Intimidator is an excellent option for removing obstructions on a task website. https://www.businesswire.com/news/home/20211115006285/en/CES-Honors-Doosan-Bobcat-for-the-World%E2%80%99s-First-All-Electric-Construction-Machine-in-Two-Innovation-Award-Categories can manage heavy trees and also various other tough jobs. Its ten-inch broad opening as well as twenty-inch deep jaw enables simple understanding of large things. This puller additionally has replaceable excavator bucket teeth as well as an upright jaw saw. The Intimidator can suit tight locations.

Keep Reading For Additional Information Regarding Skid Steer Tree Puller

A skid Steer tree puller is an efficient tool for eliminating trees as well as various other vegetation from your yard. The puller permits you to precisely pull out a details plant without damaging others. Its operating capability is higher than other tree pullers, so it can deal with much heavier items than common ones. Normally, little trees can be removed with little problem. Big trees, nevertheless, might need more power and also may be difficult to get rid of.

An additional good use for a skid Steer tree puller remains in demolition. Numerous building and construction tasks require elimination of deep messages. The skid Steer tree puller enables this to happen quickly and securely. You won't need to work with several workers to do the job, permitting you to reduce labor expenses. Making webpage of a skid Steer tree puller is likewise a terrific method to shield your landscaping plans from being ruined by stray trees.

If you're looking for a skid Steer tree puller, a couple of various designs are readily available. Bucket Solutions makes a specialized tree puller that hooks onto your skid Steer's pail. Unlike various other accessories, the Container Solutions is not hydraulically powered, yet uses the skid Steer's pail to pull out trees with ease. You can choose the ideal one based upon your job needs.

Titan Attachments makes a skid Steer tree puller accessory that features a lifetime guarantee. It is compatible with many sorts of skid guides, and can pull trees between one and six inches in diameter. Nonetheless, it's important to keep in mind that the Titan isn't as effective as various other tree pullers, as the hydraulic components can be damaged and leakage. This skid Steer tree puller is a good alternative for a little farmer or professional seeking a reputable add-on.

As a general regulation, skid steers are versatile and also very functional. Their several add-ons allow them to do various work, from removing land to getting rid of huge trees. They are also helpful for removing various other types of greenery, such as shrubs and weeds. If you're searching for a tree puller accessory, think about reading the individual's handbook or getting in touch with the maker straight. By doing this, you'll understand whether the add-on is right for your requirements and needs.

The GreyWolf(tm) Skid Steer Tree Puller Attachment is a durable piece of equipment, created from 3" x 3-inch steel tubes. It connects to a standard universal quick-adjustment. This accessory utilizes the power of the skid Steer to draw a tree and is made to last. The GreyWolf(tm) Skid Steer Tree Puller Attachment is an optimal option for anyone aiming to obtain a rapid as well as reliable tree removal option.

The Brush Grubber is one more skid Steer tree puller attachment that is cheap and durable. It's not quite as effective as a hydraulic tree puller, yet it's an effective tool for smaller sized drawing tasks. However, it's finest to buy a hydraulic tree puller if you're intending to do several tree pulling jobs with it. For an advanced version, take into consideration the Bucket Solutions skid Steer tree puller. While it might be less costly than hydraulic tree pullers, it's still not as versatile as the Brush Grubber.

While the Heavy-Duty Tree Puller is a versatile tool, the equipment's jaws have adequate power to pull out intrusive trees, messages, as well as even concrete blocks. The hydraulic cylinder provides 3000 pounds of clamping pressure. This hydraulic tree puller has durable jaws to collect origins and also relocate foliage. It also features a sturdy AR400 blade. It is also developed to secure hydraulic hoses away from the jaws for optimum safety.

The Boss hydraulic tree puller comes with jaws that are made of 1" thick steel. The jaws are made from AR400 steel and also can endure 60,000 extra pounds of force. The device's front spade allows the driver to dig around a huge tree. They can break up origins as well as liberate obstacles before securing the tree to the skid Steer. As well as, because it can additionally be used to get rid of fence messages, this device is a terrific enhancement to any kind of yard or garden.

Listed Below Are Some Of The Most Usual Accessories For A Skid Guide For Landscaping And Farming

A skid guide is a terrific machine for landscaping and farming. These equipments are capable of chipping wood as well as grinding stumps, as well as tilling dirt and also using plant food. They likewise include buckets as well as other landscaping devices for moving products. Read Far more can be used by both amateurs and experts. Continue reading to read more concerning these functional devices.

https://www.businesswire.com/news/home/20211115006285/en/CES-Honors-Doosan-Bobcat-for-the-World%E2%80%99s-First-All-Electric-Construction-Machine-in-Two-Innovation-Award-Categories of the skid guide as well as the height of the dump truck will certainly establish its packing capacity. For extensive demolition job, a larger skid guide is required. A wheel loader can carry out most excavation work and also maneuver on a work site without the aid of a vehicle. You can find overviews to select the best skid guide for your demands, or you can talk directly with suppliers for guidance. Whether you are intending a house renovation project or a demolition task, there's a perfect skid steer for your demands.

Designed in 1957, the initial skid steer was originally a three-wheeled loader. The siblings, who came from a farming family members, were appointed by a neighborhood turkey farmer to develop a machine to help him walk around the ranch. Ultimately, Melroe Manufacturing bought the patent on the equipment and began working with its automation. With so many features, the skid steer is still the leading option for service providers.

A skid guide serves for both interior and exterior demolition projects. The demolition shears are a convenient function of this type of tools. They can cut through various sorts of material easily. Along with this, skid steers can likewise be geared up with a cement mixer or sidewalk miller. Adding a skid steer to your project can improve your productivity no matter the season. Once you have actually purchased a skid steer, you'll have the chance to expand its capabilities and conserve money while completing a task.

There are 2 primary types of skid steers: rolled and also tracked. Rolled designs set you back much less to purchase and have lower maintenance costs. However, if you're operating in a severe terrain, you may be better off renting out a tracked design. They cost much less to preserve and don't damage easily. Compared to track loaders, they're a lot easier to transfer. The tracks on rolled designs are likewise less complicated to clean up.

The advantages of skid guides are numerous. Their compact dimension as well as dexterity make them ideal for a large range of tasks. Several are likewise geared up with blades, rakes, snow blowers, and also stump mills. Caterpillar is among one of the most trusted hefty devices brands worldwide. Feline offers state-of-the-art rental devices for skid steers. If you remain in the marketplace for a skid guide, think about leasing one today.

While skid steers have come to be identified with bobcats, their beginnings are a little bit much more obscure. Bobcat began life in 1947, with Edward Gideon "E.G." Melroe, a previous grease monkey that passed away in 1955, established a company called after him. This firm later partnered with the Keller brothers, two turkey farmers in Western Minnesota. They created the initial skid guide, called the Keller Loader. In 1958, both firms began manufacturing the Keller Loader, as well as they turned into one of one of the most reputable names in hefty tools.

The name "skid steer" describes the means a skid guide turns. Considering that the skid steer wheels are repaired, the driver has to boost speed to the side with which he's functioning. The increased rate of one wheel makes the maker skid. Eventually, this characteristic is in charge of its ability to transform a zero-degree span. However, it is very important to keep in mind that skid steers call for some training before running effectively.

A medium-frame skid steer is perfect for bigger jobs as well as can likewise be furnished with different add-ons. It can perform the features of a backhoe or a miner. They are lighter than various other hefty equipment, so they can be conveniently maneuvered in tight spaces. They can likewise be utilized to dig via asphalt and also concrete. Its ROC is about 1,300 to 1,900 extra pounds. When contrasting, medium and also large-frame skid guides have similar capacities to every other.

When considering skid steer rental, make certain to take into consideration the number of hours you plan to use it. Numerous rental firms offer skid guides with a range of add-ons. You can acquire these separately or lease them as a plan. Renting out skid steers with add-ons is a terrific alternative if you wish to broaden your company. You can use these makers to do a selection of tasks and also earn extra revenue while preventing storage prices.

Why Skid Steer Is A Flexible Piece Of Equipment For Any Type Of Landscape Project?

The background of the skid Steer began in 1957, when a small turkey farmer asked Keller Brothers to design a machine to aid him out. The Keller brothers, understood for their fabrication skills as well as inspiration, came up with a layout that consisted of 2 front wheels as well as one back wheel. They sold their invention to local Devices Dealer Melroe, that hired Keller Brothers to more refine the concept. The outcome was the skid Steer that is used today by thousands of contractors and farmers worldwide.

A skid Steer can be utilized to do countless tasks, from loading openings to leveling the ground. If you wish to level the ground without trenches, a rake or grading bar add-on is perfect. For low-level work, a radial lift skid Steer is better. This attachment is made to relocate dust, compost, and also rock easily. You can additionally attach a rake to the machine for easy scooping up rocks and also leveling the ground without making a trench.

The dimension of the jobsite will assist you establish what class of skid Steer is best matched for your needs. You must recognize just how much elevation, dumping height, and also hydraulic capacity are required to finish the job. You likewise need to recognize what jobs the skid Steer will be carrying out. You can also take into consideration whether you need to employ a damp hire driver. It is very important to make sure that they are certified and insured, and also iSeekplant gives drivers with full credit.

There are a selection of dimensions and models of skid steers offered for lease. Relying on the dimension and weight of the job, mid-sized skid guides are a good option for small-scale digging projects and smaller demolition tasks. Larger versions are optimal for large-scale demolition tasks, yet they are not as portable as various other utility automobiles. Choosing a smaller sized structure and radial lift is better for tight areas.

The Volvo C-Series skid Steer line is available in 5 models for North America. 3 versions are rolled as well as have operating capabilities of 2,250 extra pounds. Both of these models have an easy-access side entrance. Moreover, they have actually boosted presence and security. Contrasted to earlier designs, these equipments are easier to steer. You can personalize your skid Steer with various add-ons, including a snow blower, a forklift, as well as a sander.

The primary distinction between a skid Steer and a routine loader is the method it transforms. A skid Steer is guided by boosting the rate of wheels on one side, and also slowing down the contrary wheel beyond. By doing this, it can turn with zero-degree span. Utilizing differential steering requires training for the motorist. If you're brand-new to steered loaders, it may be handy to take a workshop class.

It can relocate hefty lots, such as rocks or boulders, or perform various other job that needs large, level surfaces. Skid steers can likewise move pallets and other materials. They can likewise work as a telehandler and also can be made use of in forestry operations. But you need to understand exactly how to properly make use of a skid Steer if you wish to maximize its productivity.

A skid Steer is a very functional piece of hefty tools that possesses two hydraulic training arms on each side. You can gear up a skid Steer with many different add-ons to make it beneficial for any kind of kind of building job. They can do everything from digging and lifting products to spreading them and also loading vehicles. As well as while this devices might be small in dimension, it's effective enough to take on any task. And also when used effectively, it can assist you finish the task faster and a lot more successfully.

Another name for a skid Steer is a portable track loader or multi-terrain loader. The differences in between both kinds of makers are based on the features of each. source web page is a small track loader with steel undercarriage components. While MTLs feature rubber undercarriages and also a lightweight steel framework, they have a lower ground stress and do not tear as conveniently as their counterparts.

Besides visit link , skid Steer loaders are additionally called compact wheel loaders and tracked skid Steer loaders. While a lot of are wheeled, tracked makers have the ability to take a trip on dirt as well as mud. They are more difficult to tip than rolled ones, however can deal with much heavier lots. Nevertheless, they are slower than rolled makers. They are likewise slower than rolled skid Steer loaders, and also they can not activate no radius.

How To Select The Passage Pasteurizers And Set Pasteurizers For Beer & Beverage Makers?

Tunnel Pasteurizers are devices that heat products such as sodas, beer, as well as acid preserves to a temperature below the point at which they are risk-free for intake. The containers are loaded onto one end of the pasteurizer conveyor belt and after that passed beneath sprays of hot water. The water is warmed at temperature levels from 60 to 100degC. The length of the pasteurization process depends upon the sort of container. To make the process effective, Tunnel Pasteurizers are made to decontaminate products as swiftly as feasible.

Big Tunnel Pasteurizers are made use of in commercial developing operations. These pasteurizers warm beer to 140F and hold it there for a predetermined period of time. After the moment is up, the beer is cooled down by being submersed in warm heavy steam or splashed with cold water. A tunnel pasteurizer is an usual part of several large-scale brewing centers. Passage pasteurizers are the most usual choice of pasteurizers.

Set pasteurizer systems commonly consist of a stainless-steel drum with a pre-heated glass carafe. The system has a condenser, channel, and also complementary devices. The majority of these systems are developed for household usage as well as come with client guides and shielded covers. linked resource site have the choice of a built-in air conditioning system. Along with set pasteurizers, there are also tunnel pasteurizers that are equipped with vapor injection.

“BATCH AND TUNNEL PASTEURIZATION FOR CIDER/HARD CIDER PRODUCTION”

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) May 5, 2022

Article Release for Brewmasters & Beverage Makers by Edward A. Michalski, CEO of PRO Engineering / Manufacturing Inc.

Click for article: https://t.co/pHlppWRUUe

PRO Engineering / Manufacturing Inc.

414-362-1500 pic.twitter.com/RURPgLJGxj

The different parts of a tunnel pasteurizer can impact the quality of the completed beer. For https://www.foodbusinessnews.net/articles/13272-high-pressure-processing-gaining-popularity-in-beverages , if the beer has been sterilized too high, it can lead to undesirable "pasteurization tastes" and also turbidity. A sterilized beer can likewise have yeast and various other impurities that can cause bottle bursting and unfavorable growth. Ultimately, this can influence the quality of the packaged item, the safety and security of the customer, and your profits.

Because passage pasteurizers are such efficient makers, they are utilized in a wide range of markets. The objective of the passage pasteurizer is to kill germs, protect against fermentation, and also keep shelf security. These equipments go through significant warmth modifications and also caustic cleansing chemicals. Furthermore, broken containers can damage the pasteurizer. Passage pasteurizers from PRO Design have years of experience in designing and also developing them.

To keep an eye on the temperature and time considered the plans to go through the pasteurizer, a pasteurization system display is used. It is composed of software and hardware that takes a trip with the item during pasteurization. It downloads dimensions to a laptop computer and also determines PUs. It likewise manages the water sprays inside the tunnel as well as can be managed. There are different temperatures and also times for various products, so it is necessary to very carefully think about the temperature and also time needed for the product to be pasteurized.

When selecting a passage pasteurizer, consider its dimension and also type. These devices can be found in a range of sizes and also measurements, as well as are based upon the type of item being sterilized. Depending on the kind of food product, tunnel pasteurizers may be a crucial part of a manufacturing process. These devices remove microorganisms, enzymes, as well as other bacteria that can make products harmful to eat. So, select the ideal one for your requirements.

Millisecond Technologies' procedure includes spraying milk right into a warmed chamber. The milk is after that heated at a rate of 72.7 degC for 20 nanoseconds. Combined with rapid depressurization, the milk is ruined of all traces of germs. Commercial MST plants can process approximately 240,000 litres per hr. At 4 degC, pasteurized milk has a shelf life of 60 days.

Historically, pasteurization was thought about an outcast strategy amongst tiny and also independent breweries. Independent makers thought that pasteurization was an unnecessary concession between flavor and also shelf-stability. The method appeared antithetical to the craft ethos when initially introduced. Craft beer continued to grow and nationwide brands came along. National circulation meant even more bottles traveling longer ranges, and drinkers came to be more daring with the dishes they were taking in. Despite this, the microbial lots in craft beer boosted. This lowered shelf-stability as well as lowered consumer confidence.

There Are A Couple Of Important Factors To Consider To Think About Before Buying A Tunnel Pasteurizer

Tunnel Pasteurizers are extremely useful in industries where the production of big quantities of sterilized items is called for. These devices operate the very same concept, pasteurizing food at heats as well as maintaining them in a trendy, completely dry environment. Passage Pasteurizers are typically integrated into a bottling or labelling line. This means that the process is highly reliable and also does not need any unique understanding or skills. There are different sorts of tunnel pasteurizers.

For beer manufacturing, Passage Pasteurizers can be especially valuable for speeding up the process. Their temperature ranges are regulated, unlike various other approaches which are largely experimentation. As a result, an extensive understanding of pasteurization processes will certainly aid ensure taste security and protection against contamination. Tunnel Pasteurizers have the advantage of making sure regular results, making them an exceptional option for a house brewery.

“TUNNEL AND BATCH PASTEURIZATION VERSUS ADDING ARTIFICIAL PRESERVATIVES TO FOOD AND BEVERAGES”

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) April 26, 2022

Article Release for Brewmasters & Beverage Makers by Edward A. Michalski

Click for full article: https://t.co/vwPs0n4WKK

PRO Engineering / Manufacturing Inc.

414-362-1500 pic.twitter.com/W9I7ksE6Xy

A Tunnel unit need to be created to provide suitable thermal therapy. Normally, passage systems will be developed as modular or monoblock structures. Some models can sterilize white wine, juice, beer, or gently carbonated drinks. The tunnel system is created from stainless steel and also comprises a number of process containers. The passage can be single-deck or multi-deck. https://lacrossetribune.com/news/local/column/paul-larson-heres-why-not-all-milk-tastes-the-same/article_b5dc2ef8-56e0-55fb-9edd-014277f8904f.html , such as shutoffs, warm exchangers, and circulating pumps, are mounted on the outside of the passage.

Craft Passage Pasteurizers are made for tiny to medium-sized breweries. They include the very same performance as their bigger brother or sisters, yet in a monoblock design. Its completely automated and advanced pasteurization process makes it a clever option for tiny and also medium-sized brewers. They are also highly effective. If you are looking for a reliable, affordable equipment to heat up your drinks, take into consideration the following pointers.

The batch pasteurizer system includes a stainless-steel drum, a stainless-steel channel, as well as a shut cover. These systems are great for residence use, and also the majority of models can be attached to a common wall electrical outlet. Tunnel Pasteurizers are easy to use and also budget-friendly. If you are thinking about getting one for your residence or industrial kitchen, it is very important to consider the price. And as the price of these makers is reasonably low, they are a superb investment.

The life span of foods is a vital specification to take into consideration. All-natural toughness is just a few days, which is why manufacturers usually add preservatives and also thermal handling to lengthen its service life. Tunnel Pasteurizers make it possible for ideal use thermal energy while saving healthy food. The modular design permits future development as well as much easier delivery. With these advantages, it's no surprise that Passage Pasteurizers are preferred with suppliers as well as food processing sectors.

Other than extending the life span of beverages, pasteurised foods can also trigger some quality issues. Depending upon the water chemistry of the passage pasteuriser, these products may struggle with rust-like places on their crowns, staining of aluminium can base domes, as well as fading of unlacquered cans. In addition, not natural salts may speed up and trigger unsightly spotting on the package.

Before the advancement of Passage Pasteurizers, the process of pasteurization was believed to be the domain name of commercial lager breweries. Independent breweries were hesitant to adopt pasteurization because it gave up flavor for shelf-stability. Nevertheless, as time passed as well as the craft beer market expanded, nationwide brand names came to be much more prevalent, indicating more bottles traveled better. Additionally, brewing techniques developed and came to be a lot more daring, including barrel aging. As the microbial lots of the beer raised, its shelf-stability likewise decreased. This decreased the money as well as customer confidence of brewers.

Listed Here Are The Benefits Of A Skid Steer

A Skid Steer is a machine that is capable of doing several jobs, as well as is often used in landscaping. It can erode stumps, chip wood, and till the ground. Some versions have attachments that can blend compost or plant food into the soil. It likewise includes a bucket for transferring products and also devices. It can likewise be made use of for light building.

Tiny Skid Steers are best used for landscaping, structure, website development, and also underground building and construction. Medium-size versions are one of the most preferred and also attribute strong wheel bearings and also engine power. They can likewise be set up to have low ground rubbing making use of unique wheels such as the Mecanum. In addition to their high-performance functions, skid steers can be outfitted with a selection of add-ons. Larger loaders can tackling larger construction websites.

Size: The capability of a skid Steer depends on the jobsite. Whether the worksite is small or huge, it is critical to understand the size of the maker required. For instance, a smaller loader would be appropriate for a little unit while a bigger machine would certainly be best for a large jobsite. Furthermore, the task itself will determine whether an upright or radial lift is much better matched to the job. Rental professionals can assist you make an informed choice based upon the job at hand.

Among the many beneficial skid Steer attachments are augers. https://www.forconstructionpros.com/equipment/attachments/cold-planers/article/12236094/properly-pair-cold-planer-attachments-with-skidsteer-loaders-and-other-carriers make excavating jobs less complicated and make certain exact openings. Their curl shape makes them simple to identify, and they preserve the integrity of the soil. Backhoes are one more valuable accessory. These heavy-duty machines can dig trenches. Additionally, their pails are generally large and also heavy, allowing them to dig numerous holes in a single day.

Regardless of its flexible capabilities, a skid Steer can be used for numerous jobs besides building and construction. Farming and landscape design are additionally common usages for a Skid Steer. Including different add-ons to it makes them a flexible piece of equipment. Using different accessories can extend the abilities of the machine, and also its versatility is just restricted by the operator's creative thinking. If a specific attachment is not in production yet, drivers can piece it together to carry out the same feature.

One of the most typical add-ons offered for skid steers are for excavating, breaking up concrete, trenching, auger drilling, as well as snow elimination. simply click the following webpage have thousands of different attachments for different tasks. A wide array of add-ons can be purchased from Lano. With thousands of various accessories, a skid Steer is a functional tool for any kind of job. The right skid Steer attachment will make the task easier and reduce the cost of the devices.

Renting Out a Skid Steer is a choice for periodic use, yet possessing one provides benefits for landscapers and also building and construction teams. While a skid Steer can be expensive to buy, its operating ability will certainly identify how much it will cost you. It must be kept in mind that the weight limitation of a Skid Steer depends on its capability. If the equipment can't manage heavy tons, renting it will aid. And also, unlike with various other hefty devices, it will conserve you money by getting rid of storage expenses.

A Skid Steer is an important tool for any type of landscape design job. By finding out about how to utilize it effectively, you can complete your landscape design task with ease and also with much less difficulty. You can discover endless usages for a Skid Steer as well as it will make your job less complicated and also a lot more reliable. For those of you who are searching for a Skid Steer, there are numerous important suggestions to remember. And also when you've mastered the essentials, you'll have the ability to get started in a large range of landscape design projects.

There are various designs of a Skid Steer. Choose the one that ideal matches your demands. Some makers make one, while others only generate a single model. Think about the operating weight and also horse power of a Skid Steer. The rated operating capacity of an equipment will certainly tell you how much weight it can lift without tipping over. There are also various accessories for a Skid Steer. A Skid Steer is an indispensable tool for lots of kinds of building and construction projects.

When Determining To Acquire A Skid Steer, There Are A Number Of Crucial Things To Take Into Consideration

Firstly, you should think about the size and shape of the jobsite. This will determine the course of the skid Steer you require. Then, you need to know whether you will certainly be discarding or lifting material. You will certainly additionally require to recognize the hydraulic ability of the maker. You will need to know what the jobs are you intend to execute with the skid Steer.

The skid Steer can be found in a variety of sizes. Small-frame designs are good for light landscaping and structure tasks. Medium-sized models are the most common kind of skid Steer and have outstanding engine power as well as balance. mouse click the following website page are fit for a selection of add-ons and also are an excellent option for many tasks. Bigger models can handle the heavy lifting and moving required on a construction site. To locate why not try this out , speak to rental specialists to get more information about their various designs as well as functions.

The rake add-ons are a fantastic choice for landscaping projects. These attachments are terrific for getting particles and also aerating and leveling the dirt. You can additionally utilize a sweeper bucket. Whether you need to rake leaves, turf, or other garden overgrowth, a Skid Steer can take on the task quickly and also successfully. A skid Steer's versatility is among its greatest assets.

There are loads of attachments for the skid Steer. These attachments can assist you achieve various jobs and conserve you cash. Depending on what you need, you can also add a cement mixer, a concrete mixer, or any other range of tools. You can even piece together various accessories for your Skid Steer to meet your demands. As soon as you've gotten your skid Steer, you'll have countless opportunities to broaden your company!

A Skid Steer has numerous uses. Backhoe attachments work excellent for light building and construction and landscape design projects. For example, you can relocate materials from one side of a building to the various other, and also rearrange them when you're ended up. If you're aiming to make a blog post hole in a concrete slab, you can use an auger accessory. With a rock head drill, you can appear even the hardest materials.

A Skid Steer can carry out a number of tasks, as well as specialized buckets can improve its adaptability. A Lano Devices skid Steer bucket can be made use of for a variety of tasks, including rock digging, blending cement, and also grinding stumps. Many of its skid Steer buckets come from relied on brand names like FFC. These brands offer top quality tools and parts for a wide range of uses. When you purchase an attachment for your Skid Steer, it is very important to select one that will certainly optimize your efficiency and also optimize its capacity.

The Bobcat brand name is associated with timeless American entrepreneurship. Founder Edward Gideon "E.G." Melroe founded the business in 1947 and also died in 1955. The business partnered with the Keller siblings of Western Minnesota to develop the first skid Steer. The Keller Loader was initially designed for turkey farmers and also was generated by Melroe Manufacturing. It was mass-produced in 1958. And the Bobcat name was taken on in 1962.

The very first crucial decision you need to make is whether you'll utilize a tracked or a rolled skid Steer. Rolled skid steers are cheaper than tracked ones, and also they are much easier to maintain. On top of that, they don't damage or harm as easily. A tracked skid Steer, on the other hand, is best for rough or challenging surface. Tracked skid steers can soar over rough or uneven ground, and also the Mecanum wheel is a great instance of low-friction.

The 155 New Generation skid Steer produced in Savannah, Georgia, can lifting up to 1,555 pounds of product. It also comes with electro hydraulic servo controls, which reduce the risk of leaks and boost machine controllability. The cab on the 115 skid Steer has a side entryway as well as can fit greater than 30 add-on family members. An additional important alternative is a hydraulic quick-hitch. The C-Series skid Steer likewise flaunts a hydraulic power-hitch choice.

The initial skid Steer was designed in 1957 by 2 bros in Rothsay, Minnesota. The brothers were known for their fab abilities and creativeness. They developed the very first skid Steer in 1957 with two wheels on the front as well as one in the back. They later offered the civil liberties to the machine to the regional Tools Dealership, Melroe, and also at some point marketed it to them. They improved it as well as mass produced it. That was then. The modern-day Skid Steer is a flexible device that is useful for a large range of jobs.

If You're A Landscaping Specialist, A Skid Steer Can Be An Useful Addition To Your Fleet

Unlike a backhoe, skid guides have a rake attachment, which is terrific for raking debris, freshening dirt, and also leveling ground. Its flexible elevation as well as rake head likewise make it very easy to empty the bucket. A radial lift skid Steer is suitable for reduced ground work.

Skid steers are commonly utilized for landscaping, and also auger attachments make it simpler to set fencing posts and plant exotic tree samplings. Furthermore, one device can likewise be utilized for rockwork, waterline installment, and grinding stumps. Skid steers are additionally utilized by building professionals, that can lease add-ons that are perfect for sawing concrete, stacking lumber, and more. Several skid guides also have add-ons for grading, including pail, tiller, as well as broom.

An additional popular skid Steer add-on is the auger, which is an essential product dealing with device. These tools assist dig message openings quicker and also much more efficiently, without the requirement for expensive forklifts. Depending upon the host machine, augers can dig as deep as 72 inches, though there are additionally prolonged augers to dig much deeper. When choosing an auger, make sure to check the hydraulic flow as well as pressure ratings of your track loader.

The sorts of skid Steer attachments readily available are numerous and functional, and also you can choose the ones that are most ideal for the job you're performing. They are compatible with the skid Steer, which suggests they can be transferred from task site to task site. Furthermore, skid guides are functional adequate to manage a variety of tasks, as well as the top skid Steer accessories are designed for landscapers, construction supervisors, and also specialists.

Buying a skid Steer is a financial investment, and also you can choose to rent the attachments independently. Relying on the dimension and also frequency of your jobs, acquiring a skid Steer can be a cost effective and also reliable alternative. Furthermore, it will certainly minimize repetitive rental charges. Skid guides additionally have lower preliminary as well as continuous costs than other kinds of portable devices. These are crucial for lots of work, but they can additionally cost a few thousand dollars.

An additional important kind of Skid Steer accessory is the rock pail. Rock pails are made use of for sorting materials, clearing rocks, and also grading jobsites. They are made to hold rock and also debris as you function, and will certainly then return it as fine soil. Rock containers can also be made use of to till soil before planting. All of these accessories can be made use of with a skid Steer. You can likewise discover various other valuable attachments by browsing through the various types.

Plate add-ons are great for installing irrigation lines, drainpipe pipes, and also underground energies. They can likewise be made use of for footings, pinning piles, as well as separating difficult ground before tilling. Choosing the appropriate trencher attachment for your job relies on the work site and skid Steer devices. Handbook and hydraulic variations are offered. Some drivers favor hand-operated plates to hydraulic plates. If you're uncertain which one to choose, check out the video listed below.

Relying on the dimension of the task you're doing, various skid steers are better for certain jobs. Small-frame skid steers are less complicated to manoeuvre in limited rooms. Medium-size skid steers are matched for interior work, landscape design, as well as website advancement tasks. On the other hand, a medium-sized skid Steer can be used as a backhoe, and its accessories can operate as a miner too. It can also be made use of on concrete as it has tires.

Generally, a skid Steer features a container as its default add-on. With an array of other tools, the skid Steer can be utilized for all kinds of building tasks. A skid Steer is an extremely flexible piece of equipment, which makes it a popular choice on a work website. The attachments you can purchase for your skid Steer will make your task simpler as well as faster. And the convenience is indispensable in a building organization.

If You're Seeking A New Accessory For Your Skid Steer, You Have Actually Pertained To The Right Place

With the Grader Blade add-on, you'll have everything you need to quality large areas of land. With a 96" blade, a control box for in-cab hydraulic control, as well as a reversible/replaceable cutting side, the Grader Blade will certainly transform your skid Steer into a high-performance grading equipment. The control box is outfitted with a symmetrical current shutoff that gradually adjusts the blade elevation and angle. This unit prepares to approve a laser control system, and also features flat face couplers.

If you just intend to use your skid Steer once in a while, you might be far better off renting a maker as opposed to acquiring one. Although skid guides are fairly pricey, their usage is uncommon and also you'll have less hassle leasing one. Rentals are additionally an outstanding option if you're not sure if you need the accessories frequently. You can work with a specialist to aid you determine what's finest for your projects.

An auger is a typical add-on for skid Steer loaders. These attachments dig openings without damaging the bordering soil. A selection of different sizes as well as styles are readily available, so it is very important to find one that matches your demands. The series of sizes and styles available will assist you take on any type of work effectively. If you're searching for a specialist grade auger, the Lano auger is the attachment for you. Along with piercing deep openings, this attachment is also fantastic for blending compost or mixing concrete.

Another vital accessory for a skid Steer is the rake. Like a giant dustpan, the rake can also be used to tidy up locations. Its bristles are turning, making it very easy to accumulate dust and also debris. You can after that dispose the dirt making use of the rake attachment, like a bucket. This accessory will certainly save you considerable time in tidying up and lessening the variety of employees required to finish the job.

One of the best alternatives for skid Steer log grapples is McLaren Industries' grapple containers. These devices are inexpensive and offer professional-grade quality. http://citysearch.com/profile/732312340/clarinda_ia/c_l_fabrication.html raise the working ability of a single machine, permitting you to complete more jobs in less time. In addition, you don't need to hire additional team or take any additional training to utilize this accessory. There are many advantages to getting rid of the grapple pail from your skid Steer.

As with any kind of tool, there are benefits and drawbacks of each kind. Some skid guides are more suitable for particular tasks than others. Tiny skid steers are better matched for interior job and landscape design, while medium-sized devices are the most effective for demolition work and demolition projects. skid steer tree and post puller are additionally lighter and also less complicated to steer in tight areas than typical equipment. A medium-size skid Steer is a great choice for difficult ground conditions such as sidewalk or concrete.

An additional skid Steer accessory is the hydraulic breaker. It can transform your skid Steer into a demolition machine. Also called a demolition hammer, a hydraulic breaker enables your skid Steer to break up concrete and also rock. The hydraulic breaker accessory matches the hydraulic ability of the provider with the breaker to ensure constant performance. You can pick from several brand names and designs, including Bobcat and Stanley. The hydraulic breaker is a terrific option for demolition jobs as well as other applications.